Wires are of two groups- (i) ordinary wires and (ii) cables. For electric work conductors are usually made of copper but aluminium conductors are also used mainly because of its low cost. In India a large quantity of copper is imported from other countries. Presently the armature and field coils of different machines and instruments are also made of aluminium wire.

However for fuse wires, use of lead-tin alloy or copper wire is the usual practise. Wires are used for the manufacture of armature and field windings of generators, motors, electrical instruments, etc., and also for house wiring and for drawing overhead transmission and distribution lines. Wires used for house wiring and underground cables have various types of insulation.

Different Types of Insulated Wires:

Different types of insulated wires primarily used for house wiring are discussed below:

1. Vulcanised Indian Rubber Insulated Wires:

ADVERTISEMENTS:

On the conductor one or more layers of vulcanised Indian Rubber (V.I.R.) i.e., rubber treated with sulphur at high temperature, is applied. For removing the bad effect of sulphur on copper or aluminium, the conductor is thoroughly tinned or a layer of pure rubber is applied on the conductor.

Finally the rubber insulation is covered either by cotton tape impregnated with moisture resisting compound like bitumen or wax, or covered with cotton tape. V.I.R. wires are single-core type and usually used in conduit wiring, wood casing and cleat wiring, etc. In recent years, however, single-core P.V.C. wires have largely replaced V.I.R. wires.

2. Tough Rubber Sheathed (T.R.S.) and Cab Tyre Sheathed (C.T.S.) Wires:

Over the tinned copper or aluminium conductor a layer of pure rubber or rubber treated with sulphur is used. As outer protective layer tough rubber sheath (T.R.S.) wires and cab tyre sheath (C.T.S.) wires are provided. These may be used in damp places or in open atmosphere. T.R.S. or C.T.S. wires are light in weight and cheaper in cost.

ADVERTISEMENTS:

These wires are available in single-cores twin-core, three-core conductor. Single-core and twin-core wires are mainly used in house wiring, and twin-core and three core wires are used for giving supply to cranes, hoists, etc. and also for drawing service connections from the overhead distribution lines or from one building to another.

The rubber insulation over each conductor has different colours for different cores. In recent years for service connections and house wiring P.V.C. wires are preferred over T.R.S. or C.T.S. wires.

3. Metal Sheathed or Lead Sheathed Wires:

In these wires V.I.R. types are provided with a continuous lead sheath covering which is mechanically strong and moisture proof. Due to its high cost compared to C.T.S. wires, lead sheathed wires are not used for internal wiring but used for service connections and for wiring under abnormal climatic conditions with high moisture.

ADVERTISEMENTS:

Lead sheathed cables are available in many forms like single-core, twin-core flat, three-core flat and twin-core flat with an earth continuity conductor. In this type also rubber insulations over the conductor have different colours for different cores.

4. Weather-Proof Wires:

Weather-proof wire is mainly used in outdoor work where the wire remains exposed to open atmosphere. These wires are of V.I.R. insulated type suitably taped, braided and compounded with weather-resisting material. The conductor is of tinned copper or aluminium over which a layer of rubber treated with sulphur is applied. Weather-proof cables are useful is industries and in outdoor wiring at low and medium voltages.

5. Wires with Thermo-Plastic Insulation (P.V.C. Wires):

ADVERTISEMENTS:

Here conductor is insulated with poly-vinyl chloride (P.V.C.), a thermo-plastic material. This type of insulation is not affected by acid, alkali, ozone, humidity or the sun rays. Rubber insulation is deteriorated shortly but P.V.C. remains unaffected as it is much harder than rubber. So additional protection like cotton tapping or cotton braiding is not required against mechanical injury. It is inflammable but when the source of flame is removed, it stops burning.

Hence proves that P.V.C. insulation does not help combustion. However, it becomes semi-melted when excessively heated and becomes brittle under extreme cold condition. For that reason P.V.C. wires cannot be used for giving connections to the heating appliances. It is also not to be used for wiring in a place exposed to weather particularly where there is frequent snowfall.

Flexible Cord and Flexible Cable:

The wire whose cross-sectional area of each strand is less than 4.28 mm2 is known as flexible cord. Stranded wire with higher cross-sectional area of each strand is known as flexible cable. It generally consists of two separately insulated flexible stranded conductors twisted together and is called twin flexible. These wires are widely used for portable appliances like electric irons, refrigerators, heaters, hand lamps, table fans, etc.

The cord is available with two different types of insulation:

ADVERTISEMENTS:

(i) High insulation, and

(ii) Medium insulation.

For pendant lamps, bracket lamps, ceiling fans, etc., wires with medium insulation are used, in general. In twin flexible sometimes three separately insulated flexible stranded conductors are twisted together. This type of flexible cord is known as triple flexible cord, and is usually used in a.c. circuits.

1. Twin Rubber Insulated Flexible Cord:

It consists of two separately insulated stranded conductors, each of which is covered with cotton insulation. Over this insulation a fine layer of rubber is applied. Cotton covering helps to prevent sticking of rubber to the conductor.

The two conductors are then embedded in a solid mass of thick rubber insulation to built up finished cord. The outer rubber insulation is of higher grade than that used for ordinary wire insulation. The rubber insulation over each conductor has a particular colour. For a two-core cable these are red and black, in general.

2. Twin Silk Flexible Cord:

It consists of two cores, each having a number of fine copper conductors stranded together. Each core is first covered with cotton insulation. Over it a layer of rubber insulation is given. The cotton insulation between conductor and the layer of rubber helps to prevent sticking of rubber to the copper conductors. The two cores are laid side by side within a thick braid of silk insulation.

3. Twin-Twisted and Cotton-Braided Flexible Cord:

In it two separately insulated wires are twisted together. Each wire has a number of fine copper conductors stranded together. The stranded conductor is covered with cotton insulation. Over it a layer of rubber insulation is applied. Cotton covering helps to prevent sticking of rubber to the stranded conductor. The insulation of a single wire is completed when a braid of cotton insulation covers the rubber insulation. The two wires are twisted together.

4. Twin Tough Rubber Sheathed Flexible Cord (or P.V.C. Cord):

This cord is resistant to moisture and has capacity to withstand much wear and tear. The cord has two or more separately insulated wires twisted together. Each wire has a number of fine copper conductors stranded together. To form a round assembly the open space in between the twisted wires is filled with jute or cotton threads and over it a loose braid of cotton insulation is given. Thereafter a layer of high grade tough rubber insulation is applied all over the cotton insulation.

P.V.C. insulated flexible cord is presently used largely in place of rubber-insulated cord. It may be directly applied over the conductor of each wire and does not affect the copper or aluminium conductors of the wires.

Paper-Insulated Cable:

Use of paper as insulating material has almost superseded the use of rubber insulation for the purpose of manufacturing power cables. This is because paper is cheaper than rubber and has lower capacitance and higher dielectric strength. As paper is very much hygroscopic, it is soaked in insulating oil before use. Moreover a metallic sheath is provided over the insulation for preventing the entry of moisture into the insulating material. Two ends of the cable are kept sealed with pumbing metal.

The metallic sheath is made of lead or lead alloy or aluminium. Over the sheath comes a layer of bedding which consists of jute tape or paper tape compounded with a fibrous material to protect the metallic sheath from mechanical injury. Over and above armouring a serving of fibrous material like jute tape impregnated with bitument compound is given. Paper insulated cables are kept underground in most cases.

Tropodur Cables:

These cables have either copper or aluminium conductors. However, in most cases aluminium conductor is used. Over it specially treated P.V.C. insulation, called tropodur, is applied. This insulation is covered by a layer of regenerated rubber or P.V.C. tape. Tropodur cable is either armoured or unarmoured like paper-insulated cable. The armouring consists of one or two layers of galvanised steel tape or steel wires.

Over it a layer of hard tropodur is given. For unarmoured cable this layer of hard tropodur is directly applied over regenerated rubber insulation or tropodur tape. The voltage grade of tropodur cables is 650/1100 volts. Recently this cable is manufactured in large scale in India and is widely used for service connection. For transmission and distribution of electric power also these cables are used. Tropodur cable may be single-cored, twin-cored, three-cored and four-cored.

Mineral-Insulated Cable:

In this type of cable copper conductor is placed within a copper sheath. The space between the conductor and the sheath is filled with magnesium oxide at high pressure. This cable is used anywhere with the help of copper clips and copper saddles. The cable runs through the concrete walls or it may be placed underground. This cable is totally fire-proof and is not damaged by mechanical injury.

Moreover, it can be safely used in kerosene or petrol godown and in factories where gunpowder or other explosive mixture is manufactured, in damp or moist place. It is used where the surrounding atmosphere is filled with fumes produced from acid or other chemicals. The only difficulty with this wire is that, it needs skilled labour as some special type of tools are utilized for cutting and sealing the conductor.

Grade of Wires:

For both house and industrial wiring 250/440 volts grade and 650/1100 volts grade wires are used, in general.

(a) 250/440 volts grade cables are used conveniently where d.c. supply voltage does not exceed 250 volts, or the line voltage of a.c. supply does not exceed 415 volts.

(b) 650/1100 volts grade cables are used conveniently where the circuit voltage exceeds 415 volts, but the pressure between line conductor and earth does not exceed 650 volts.

In our country cable-manufacturing company manufactures cable following Indian Standard Specifications.

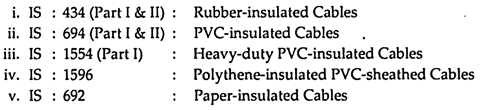

The numbers of specifications are as follows:

Size of Wires:

If current flows through a conductor, it gets heated which is proportional to the square of the current. There is a limit to the degree of heat which a particular insulation can safely withstand. According to specification of the Indian Standard Institution the maximum currents that can flow through the wires of different sizes with different types of insulations are fixed. If this specification is not followed there is a possibility of damage of the insulation for excessive heating of the conductor.

One of the methods to express the size of electric wire is in terms of Standard Wire Gauge (S.W.G.). Commonly used gauge is the British Standard Wire Gauge. To determine the wire gauge number, a circular steel disc with different sizes of holes all along its periphery is used.

Each hole has a slit attached to its side. Different slits have different widths. In front of each hole there is a number used for determining the gauge number. In practice a wire is drawn through different slits and the number mentioned against a slit in which the wire is neither slack nor too tight is the gauge number of that wire. As for example, if the number against a slit in which the wire is neither slack nor too tight is 22 the size of the wire is 22 S.W.G. If the wire consists of a single conductor, it can be expressed as 1 /22.

Now-a-days the size of a wire is not expressed S.W.G. number, but in terms of diameter of each strand.

Allowable Voltage Drops in Different Electric Circuits:

i. Drop of Voltage in Lamp Circuits:

According to Indian Standard Institution the size of the wires should be such that from the consumer’s terminals up to any light point the voltage drop shall not exceed 3 per cent of the voltage at the consumer’s terminals when maximum current flows through the circuit.

ii. Drop of Voltage in Heater Circuits:

Similar to lamp circuits in heater circuit also the voltage drop from the consumer’s terminals up to any load point shall not exceed 3 per cent of declared voltage at the consumer’s terminals. Thus if the declared pressure at the meter board in a house be 230 volts, then 3 per cent of this voltage is (230 x 3/100) = 6.9 volts which is nearly 7 volts. So the voltage at the terminals of any lamp or heater shall not be less than 230 – 7 = 223 volts.

Permissible Maximum Temperature-Rise in Wires or Cables:

If a wire is excessively heated, its insulation may be damaged. A wire of particular type of insulation may be used in places where the ambient temperature does not exceed a certain limit. This is presented in Table 29.1. If the temperature of the surrounding atmosphere becomes more than the maximum limit shown in the table, the insulation may be damaged.

If the wiring of an electric circuit is done in a way so that the heat produced in the conductor cannot be easily radiated to outer atmosphere then the size of the conductor should be selected properly. The rise in temperature of the wire in that case must be much less than the maximum allowable temperature rise. Both the allowable voltage drop and the allowable temperature rise are to be taken into account carefully at the time of selecting the sizes of different wires and cables.

It should be pointed out that if the cross-section of the conductor of a wire is equal to or greater than 0.01 sq. inch, the lead of the cable is connected to a terminal through a socket soldered with the lead of the conductor.

On the other hand if the cross-section is less than 0.01 sq. inch, either a socket is soldered with the lead or all the strands of the same conductor are soldered together, as otherwise one or two strands may not be connected with the terminal. These loose strands in turn may come in contact with the earth or with any other conducting material creating a short-circuit.

Wires Which Cannot be used in A.C.:

The following two types of single-core cable cannot be used for a.c. wiring except in earthed concentric wiring in which the sheath forms the return conductor:

i. Cables sheathed with brass or copper, and having a conductor of nominal cross-sectional area more than 0.2 sq. inch.

ii. Cables armoured with steel wire or tape.

A Comparative Study between Copper and Aluminium as Conducting Material:

Both copper and aluminium are widely used as electrical conductors. But due to lack of good quality copper in sufficient quantity in different electric work use of aluminium is being increased.

We can make a comparative study between them in the following manner:

(a) Copper has many good qualities like ductility and high tensile strength. It is not easily abraided and corroded by the atmosphere and can be readily soldered.

(b) Electrolytic copper is used in different electric works. Its colour is red and is much harder than aluminium.

Aluminium used in electric work has a purity of 98.5%. Its colour is white and is much softer than copper.

(c) For carrying same amount of current an aluminium conductor needs much larger cross- section than copper conductor. But for equal volume, aluminium has about 50 per cent of the weight of copper. This is why it always costs less if aluminium conductor is used in place of copper conductor to carry the same amount of current in the same circuit.

(d) For same cross-section, aluminium has 61 percent of the conductivity of copper. A current of 155 amperes can pass through one square centimetre cross-section of copper conductor, but through one square centrimetre cross-section of aluminium conductor only 94.5 amperes can flow.

Solid Conductor and Stranded Conductor:

If a wire or a cable has single solid conductor within the cover of the same insulation, it is called a solid cable while if the wire or the cable has a core consisting of a number of conductors of smaller diameter stranded together within a cover of the same insulation, it is known as a stranded cable. Each conductor of the stranded wire is called one strand. Total number of strand may be 3, 7, 19, 37, 61, 91, 127 and 169.

The use of stranded cable in place of solid cable has many advantages as stated below:

i. For the same cross-section the current-carrying capacity of a stranded cable is higher than a solid cable.

ii. A solid cable has single solid conductor. When that conductor is broken, the cable does not work. But if one or two strands of a stranded cable are broken, the electrical continuity of the circuit is completed through the remaining strands and the cable can still be used in the circuit.

iii. A stranded cable is more flexible than a solid cable. In fact, it can be bent without any risk of the breakage of conductor.

Table 29.2 reveals the current-carrying capacity of tropodur cables with aluminium conductors.

Wiring Accessories:

(a) Switch:

It is a manually operated device used to make and break an electric circuit.

Electric switches are classified into two types:

(i) Knife switch, and

(ii) Tumber switch.

A tumbler switch is appropriate for carrying current of 5, 10 or 15 amperes while a knife switch is used in the circuit where the current exceeds 15 amperes. The smallest size of the knife switch can carry a current of 15 amperes continuously. Knife switch is subdivided as quick break switch and slow break switch. The slow switch is also named as link switch.

(b) Quick Break Knife Switch:

It is used on the main switch-board of a low voltage circuit. A double pole quick break knife which consists of one, two or more copper blades fixed with a handle. These are the main blades whose cross-section depends on the circuit current. Each main blade is associated with one smaller blade, called auxiliary blade which is not fixed with the handle but attached to the main blade by a spring.

The main blades along with the auxiliary blades can be pressed into forked terminals or jaws at the other end. The whole thing is fixed either on a piece of ebonite sheet or a marble slab or on a switch-board panel. The moment the circuit is switched off, the handle moves in a manner so that the main blades come out of the forked terminals. But the auxiliary blades still remain into the jaws and thus maintain connection.

Then the handle is moved further out and at one point the auxiliary blades come out of the terminal contacts due to spring tension and remain to contact with the main blades again. In this way the spring provides a quick break action due to which no electric arc can be formed between a blade and a forked terminal at the time of breaking a circuit.

The basic difference between a quick break switch and a link switch is that the quick break switch has spring for quick action but the link switch has no spring attached to its blade. These switches may be single-pole, double-pole, and triple-pole and double-throw type.

If in a place there is risk of fire due to spark coming out from the switch contacts or if the circuit voltage is so high that the open contacts of the switch may be a source of danger to human life, the complete assembly of a link switch is enclosed in an iron box. This type of switch is known as iron-clad switch or a metal-clad switch.

Inside mines and also on the main and sub-distribution boards this switch is generally used. For safety the outer iron cover is connected to earth. The lid of the iron box so long remains open, the switch cannot be placed at the on-position. When the switch is on, the lid of the iron box cannot be opened and thus it becomes a fool-proof arrangement.

(c) Main Switch:

A linked switch for carrying full load current of the circuit continuously and of approved voltage grade is installed near the supplier’s meter board. This switch may be double-poled, triple-poled or triple-poled with neutral link a metal-clad double-pole switch while a metal-clad triple-pole switch. The base of the switch has fuse grips in all the lines excepting in the neutral line.

Fuse wires of suitable size are given in all the grips. The metal cover of the switch is made in a manner so that its lid cannot be opened so long the circuit remains switched on. This arrangement is required for safety purpose. The lid of the switch can be opened only if the circuit is switched off.

If the circuit current is up to 200 amperes the insulation surrounding a switch contact is air and so this switch is called air break switch. If the circuit becomes more than 200 amperes, the switch contacts remain immersed in oil and then the switch is called oil break switch. The handle of a main switch is pushed up when the circuit is ‘switched on’, and pressed down when the circuit is ‘switched off. The blades of a switch are attached to a single handle so that the flow of current starts and stops through them simultaneously.

(d) Tumbler Switch:

The switch has two brass contacts screwed to a porcelain or a bakelite base. Current flows in the switch through one contact and flows out through the other contact. A copper or brass blade is fixed up between these two contacts so that when a brass lever attached with the blade and having insulated top is pressed down, the blade is inserted between the contacts and then the circuit is switched on. For switching off the circuit, the lever is pushed up so that the blade is detached from the switch contacts.

The smallest size of tumbler switch can carry current of 5 amperes continuously. These switches can be used in light and fan circuits. Nowadays a new type of tumbler switch is used whose shape is like a piano key and called piano-key switch as shown in Fig. 29.8(a). The base and the cover of a piano-key switch are mode of moulded plastic. Its contacts are fixed on the base and the blade is attached with the inner side of the cover.

A modification of piano-key switch is the finger-touch switch. The knob of a finger-touch switch is circular in shape. When the knob is pressed, the circuit is switched on, and pressing the same knob again, the circuit is switched off.

Essential Qualities of a Switch:

The following are the essential qualities of a switch:

i. The base of a switch must be made of strong, non-inflammable, non-hygroscopic and good insulating material.

ii. The blade of a switch must not be excessively heated when carrying continuously the rated current of the circuit.

iii. All current-carrying parts of a switch must be covered by non-conducting material. In case of metallic covering there should not be any spark between the switch contacts and the cover.

iv. Electric arc of permanent nature should not be formed between the contacts when the switch is opened at a pressure 10 per cent above the rated voltage while carrying a current 1.5 times the normal rated current.

Positions of Switches:

It is better to follow a particular system at the time of placing switches at different positions in the wiring system of a house. The best position of a switch-board controlling the light point of a room is on the wall by the side of the entrance door.

This is because while entering into the room one can switch on the light conveniently just after opening the door and while going out one can switch off the light first, then close the door. Besides the heights of the switch-boards should be same which from 1.1 to 1.15 metres. In school buildings and in other similar places the height may be increased to 1.3 to 1.5 metres for the sake of safety of the children.

Fuses or Cut-Outs:

The current flowing through a circuit is not always maintained constant. It varies with the supply voltage and also on the circuit resistance. In a circuit the loads are, in general, connected in parallel. If more and more loads are connected the equivalent resistance of the circuit decreases and the current rises.

If the load is gradually increased a stage may appear when the current will increase to such a high value that the heat produced by the current may burn out the circuit. In case of a short-circuit, i.e., when the two supply lines are joined together through negligible resistance, the line conductors are instantaneously burnt.

For protecting a circuit and the apparatus connected in it, small pieces of wires are used in series with the live line at different points of the circuit and the sub-circuits. If the current exceeds a pre-determined maximum value, these pieces of wires melt and thus the flow of current is stopped.

In this way it saves the circuit or the sub-circuit from being burnt out. Such a wire is known as a Fuse Wire. This wire disconnects the circuit from the supply source and makes the circuit dead, it is also named as cut-out. Therefore no circuit shall be connected to a supply source without any fuse or cut-out.

Different Types of Cut-Outs:

There are many types of cut-out in use. A particular type is chosen according to nature of work. Fusing cut-outs are not used in distribution fuse boards or in main switch-boards.

Drawbacks in the use of Cut-Outs:

The use of ordinary cut-out has some disadvantages as stated below:

i. After melting the molten metal of fuse element scatters around.

ii. The short-circuit condition of a circuit persists for a while as the fuse element takes time to melt.

iii. The fusing current of a fuse-wire cannot be found with high precision.

iv. It takes time to replace a melted fuse element causing a loss in working hour.

v. The hot gas that comes out due to melting of a fuse-wire is to some extent injurious to health.

Different Metals used as Fuse-Wire:

(a) Silver as Fuse-Wire:

As a fuse wire silver is a satisfactory material. It is not subjected to oxidization and the metal does not deteriorate when used in dry air. However, if the air is moist and contains hydrogen sulphide, a layer of silver sulphide is formed at the surface of the element. Thus shields the metal from further attack. The only drawback in its use is that it is too costly in comparison to other metals used for the purpose.

(b) Copper as Fuse-Wire:

It is widely used as fuse-wire, particularly in distribution fuse boards and in main switch boards. The fusing current of copper wires in air. Up to 0.4572 mm diameter the length of the fuse-wire should be 63.5 mm to 90.0 mm. For large diameter the length of wires should not be less than 100 mm.

(c) Lead-Tin Alloy as Fuse-Wire:

It is used, in general, for the protection of final sub-circuits and small appliances where the current rating is low. The main disadvantage is that due to softness the molten metal is likely to scatter around when the element melts. Lead-tin alloy containing 37 per cent lead and 63 per cent tin is most preferred for fuse element. Such an alloy is called eutectic alloy. The approximate fusing currents of wires made of 75 per cent lead and 25 per cent tin.

Ceiling Rose:

Ceiling rose is used only in those circuits where supply pressure does not exceed 250 volts. Only one flexible cord is connected with a ceiling rose. Within a ceiling rose no provision of a fuse wire is provided. A ceiling rose consists of a circular porcelain (or bakelite) or plastic base with two or three brass terminals separated from each other by a porcelain (or bakelite) or plastic bridge. There are two terminals for a two-way ceiling rose and three terminals for a three-way ceiling rose.

The base is mounted on a wooden block fixed on the ceiling beam or on the wall. It remains covered with a central hole through which the flexible cord passes. Each terminal plate of the base is provided with a metallic sleeve. The wires enter into the ceiling rose from the back through the mounting block. With one binding screw the neutral wire is connected while with the other binding screw the wire from the switch is fixed.

The other side of each terminal plate is provided with a clamping screw. The flexible cord is joined with the clamping screws of the two plates. There are holes in the insulating bridge through which the flexible cord is passed through before it is joined with the terminal plates.

A ceiling rose is placed on a ceiling beam to provide a tapping to the pendant lamp holder or a ceiling fan. It is also placed on a wall for providing connection to a fluorescent tube.

Flexible Cords Used with Ceiling Roses:

For variety of purposes, different sizes of flexible cords are used with ceiling roses as shown in Table 29.4.

A suitable size of flexible cord is required to choose, otherwise the insulation over the conductors will deteriorate quickly when the cord will carry full-load current continuously.

Lamp Holder:

Lamp holders are used to connect lamps with the supply lines. The body of a holder is made by brass or ebonite or backelite. It has moulded or porcelain interior socket with a solid or spring plunger and brass terminals. The two ends of connecting wire are joined with these terminals by screws.

The top of the holder is covered with a cap having a central hole through which the connecting wire is drawn up to brass terminals. A threaded ring is provided to carry the lamp shade which is called shade carrier. Between two rings the shade remains pressed and attached with the holder.

The holder used for a pendant lamp suspended from a ceiling rose by flexible wire is called Pendant Holder. When it is used with a wall bracket, it is called Bracket Holder. A second type of holder is placed directly on wooden batten or ceiling beam, known as Batten Holder.

Many types of lamp holders are available. For lamps up to 150 watts Bayonet Holder is generally used. In India bayonet holder has the largest field of application.

Wall-Plug or Socket-Outlet:

For connecting portable appliances like table lamp, table fan, electric iron, etc. wall plug is used. It is also known as socket outlet. It has two parts: one is socket and the other is plug or shoe.

A plug with two pins is known as two- pin plug where current enters into the appliance through one pin and flows back to the supply through the other pin. The third pin in a three-pin plug is used for earth connection.

Distribution Fuse Board:

To connect different sub-circuits of a house wiring system with low voltage sub-main lines originating from the main switch, a distribution fuse board is utilized. Such a board is also called distribution board.

In a house where the total load is less than 4 kilowatts, the supplier gives supply at 225 volts d.c. or 230 volts a.c. The supply comes to the consumer’s main switch through house service meter. For distributing power at different parts of the house two wires are taken out from the main switch up to distribution fuse board.

These wires are known as sub-main lines. From the distribution fuse board different lines are drawn up to different load terminals through junction boxes. Number of sub-circuits basically depends on total load.

It is a rectangular box made of wood or sheet steel or cast iron. If sheet steel or cast iron is used, the box is to be connected to earth. Inside the box two copper or aluminium or brass bars remain fixed on insulators which are called bus-bars. With one bar the live line and with the other bar the neutral line of the sub-mains are connected by washers and machine screws.

The size of the bus-bars are so chosen that these are not excessively heated when full-load current flows continuously through them. With the live bus-bar the fuse units or kitkuts are attached. The number of kitkuts is equal to the number of sub-circuits plus one extra. One end of each kitkut is connected with the live bus-bar by brass screws, from the other end the live line of the final sub-circuit is drawn out.

If a short-circuit or any other fault occurs in a sub-circuit, the fuse- wire of that particular sub-circuit is burnt out only and the flow of current through it is stopped. The other sub-circuits remain undisturbed and the loads in those sub-circuits operate as before. The extra kitkut provided in the distribution board is used in future expansion of the load circuits.

Use of Different Switches:

Generally tumbler switches are of three types:

(i) Single-way Switch which can send current to only one circuit,

(ii) Two-way Switch which can be used to control a light point from two different places, e.g., stair-case light, and

(iii) Intermediate Switch which are used to control a light point from three or more different places.

For a correct connection switch should be placed in the live line as shown in Fig. 29.17. Connection of a double-pole switch is revealed in Fig. 29.18 while connection of only one lamp, a tumbler switch and a ceiling rose is shown in Fig. 29.19.

The Limits of Live and Neutral Wires:

While the wiring is in progress, an outer colour is normally used for identification of live or phase wires. Red colour is usually used for the live wire and black colour for the neutral wire. Having observed this colour code at the time of wiring, just a look at any portion of the circuit beginning from the terminals of the distribution board up to the farthest point of the load reveals whether it is a live wire or a neutral.

The wire from the live terminal Tumbler Switch of the distribution board up to one terminal of lamp, fan, motor or wall-plug with the switch in the ON- position is taken as live wire of phase wire. The wire from the other terminal of any of the above loads up to neutral terminal of the distribution board is taken as neutral wire.

Sometimes the wiring may become so complicated that a part of it may be considered neither live nor neutral, and specially so when the switch is in OFF position. In that case it becomes advantageous if a third colour is used in such parts.

Fig. 29.19 shows only the scheme of connection. The actual wiring must include many details. The switch for the lamp in a room is usually installed on the wall at a height of about 120 cm from the floor level (i.e., up to the shoulder of a man of average height). Suppose the lamp will remain suspended from the ceiling at the centre of the room and two wires will be led from below along a wall. With the same schematic diagram, the actual wiring will assume a different sight. Fig. 29.19 shows the wiring diagram of such a connection.

Use of Switch for only one Point:

The connection diagram for only one lamp point or a fan point will be as shown in Fig. 29.20. In case a fan has a regulator, a rectangular wooden board is to be fixed on the wall. The switch and the regulator of the fan are mounted on this board, and the regulator remain in series with the switch. The live wire connection will reach one terminal of the fan through the switch and the regulator.

If there be a long corridor which is to be illuminated by three lamps at three different points, and if each lamp be controlled by its own separate switch then the connection diagram of the arrangement will be as shown in Fig. 29.20.

Control of a Number of Points by a Single Switch:

When a number of lamps are to be switched on or switched off at a time, the wiring circuit of all the lamps should come under one switch. This can be done in two different means as shown in fig. 29.21. In Fig. 29.21(a) lamps are connected in series while in Fig. 29.21(b) those are connected in parallel.

Control of a Light Point from Different Places and Bed Switch:

In order to control a light point from two different places. Aaspecial connection is to be done. For Fig. 29.22 shows a connection of stair-case light. The lamp may be switched ‘ON’ and ‘OFF’ from two difference places.

Similarly, a lamp may be switched on and off from three different places by using circuit shown in Fig. 29.23.

A real bed switch is in the shape of a small egg or guava or of oblong form. Two long narrow strips of brass are affixed to the two terminals of this switch. In between these two strips a brass disc like a toothed wheel, is so fixed that on pushing a small lever of bakelite or plastic, the disc turns quarter of a revolution. As a matter of fact, two narrow brass strips are in electric contact with each other through the disc and the lamp lights up. Connection of a bed switch is shown in Fig. 29.24.