Locating devices are usually made of casehardened steel and separate from the jig or fixture; accurately ground and accurately positioned in the jig or fixture body.

The typical locating devices used for jigs and fixtures are:

(1) Locating buttons.

(2) Adjustable locators.

ADVERTISEMENTS:

(3) Locating pins.

(4) Conical locators.

(5) Diamond and pin locators.

(6) Profile locators.

ADVERTISEMENTS:

In jig and fixture design, it is not always possible to clamp the work directly to either the base or one of the walls of the fixtures, e.g., the surface may not be machined at those places where it is most convenient to effect the clamping.

Further the presence of chips between the mating surfaces can cause misalignment. Further if the locating faces are inclined at more than 90° then the misalignment error will be more than the thickness of the chip adhering between the inclined surfaces.

In such cases, when the reamed or finely finished holes are available, locating pins may be used for positioning purposes. In the locating pins, the location diameter is made a push fit with the hole with which it engages.

The shank of the pin is driven or pressed into the jig or fixture body and the locating diameter should always be larger than the shank in order to prevent the pin from being pushed into the jig or fixture body. The locating buttons can be either press fit type or screwed type. These are generally used for the location of flat surfaces.

ADVERTISEMENTS:

Some clearance is always provided so that chip at the corner of the job would not affect the location. The screwed type of locating buttons are used where wear and tear of locating buttons is more and it is to be replaced at quick intervals. However, cylindrical fits are best for exact locations and not the threads as these can’t align the job properly.

Jacks or pins are also employed for locating jobs and are raised in jig body to support the work beneath the clamps. Thus the support pins and jacks enable the component to be supported at convenient points.

ADVERTISEMENTS:

The locating pins can be of the following types (Refer Fig. 28.27):

(a) Fixed type,

(b) Adjustable type,

(c) Spring loaded type,

ADVERTISEMENTS:

(d) Equalising type and

(e) Taper pin attachment type.

Fixed or solid supports are easier to use. This is used when a machined surface acts as locating point.

The adjustable pin type arrangement is very simple and cheap and is comprised of a knurled head screw and a knurled nut. The screw is raised by hand until it meets the component and is then fixed in position by screwing down the lock nut.

The adjustable supports are used when the surface is rough or uneven, such as in cast parts. Adjustable locators are normally used with one or more solid locators to allow any adjustment needed to level the work.

Spring loaded type pins are used in connected with components having features subject to variation such as un-machined faces. The pin is operated through a compression spring and it positions itself automatically as it is raised by compression spring situated beneath it.

Upon assuming its correct relative position, the pin is prevented from dropping by turning the locking clamp, which forces a pin, on which an angle is machined, against a flat of the same angle provided on the jack pin. To prevent the locking pin and the jack pin from getting out of position with each other, a keyway, into which a small dowel peg is screwed is milled in each of these parts.

Equalising supports (Refer Fig. 28.28) are a form of adjustable supports but they provide equal support through two connected contact points. In this case, the two locating points are supported by the tapered surfaces, so that as one point is depressed the other raises and maintains contact with the part. Such a support is necessary with uneven cast surfaces.

In the case of taper attachment type locating pin arrangement the setting of the jack pin is done by pushing the hand wheel along with the taper pin attached to it, towards the jack pin, as a result the jack pin riding up the taper pin is raised until it touches the work.

It is then prevented from dropping by a turn of the locking nut (hand wheel), which opens the split of the taper pin, thus locking it in position. Taper pin is prevented from turning by a dowel peg in a key way.

Pin type locators are used for smaller holes and for aligning members of the tool. When pins are used for alignment, special bushings should also be used so that, they can be replaced when they wear. Alignment pins usually have a larger bearing contact area.

Pins used for part location are made with either tapered or rounded ends; allowing the parts to be installed and removed easily. Locating pins usually have a contact area of 1/8 to 1/2 of the part thickness, otherwise placement and removal of part becomes difficult.

The conical locating pin is the most commonly used type of locating pin having shouldered end. The shoulder is provided to prevent the pin from being pushed into the fixture by the work. The conical pin is used where tolerance of the hole is wider. By its use, the operator can apply the work to correct position more readily.

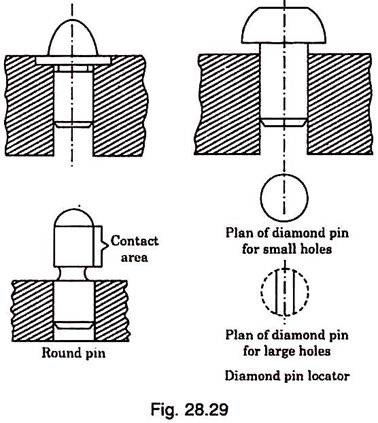

Diamond or relieved pin locator. The pin is not exactly conical but rounded at the top for small diameter holes and reduced to segmental type for larger diameters as shown in Fig. 28.29. This pin is normally used along with the round type to reduce the time taken to load/unload the tool and the round pin locates the part and the diamond pin prevents the movement around the pin.

When component parts are of heavy nature and it is only possible to slide them into the jig or fixture, it is of advantage to use disappearing pins in which the pin be covered or raised by rotating a clamp.

Profile Locators:

They are used to locate work from an external profile or outside edge which is the most common method of locating work, particularly in the early stages of machining. Profile locators position the work in relation to an outside edge/detail (like hub or boss). Nesting is the most accurate form of locating device for profile location. Ejectors are required to be used to remove work from close fitting locators (as in the case of full nests).

Vee-Locations:

It is used for locating a component having circular of semi-circular profile. The two types of vee-locations in common use are fixed type and sliding type. In fixed vee block type location shown in Fig. 28.31, the block is secured to the jig body by means of cap head screws and dowel pins.

In order to facilitate the assembly of the jig and to eliminate the possibility of the part being moved by accident, it is advisable that the vee blocks be tongued. When it is desirable that the vee block tends to hold the component downwards or ensure that the top of the vee overhangs the component for clamping purposes, then the locating faces should be angled by about 3° as shown in Fig. 28.31.

Typical sliding vee blocks are shown in Fig. 28.32. In the first type, it is actuated by means of a hand-operated screw and the second type is cam-actuated. The spring bearing against the fixed pin is fitted to return the vee block when the cam is released.

Before choosing any type of locator (stop or support) the tool designer must consider the shape and surface of the part and the type of clamping device to be used. The support selected must be strong enough to resist both, the clamping pressure and the cutting forces. To avoid distortion or bending of a part the clamps should be positioned directly over the supports.