This article throws light upon the six main types of sanitary fittings. The types are: 1. Washbasin 2. Sinks 3. Bath Tub 4. Flushing Cisterns 5. Water-Closet 6. Urinals.

Type # 1. Washbasin:

The wash basins are available in various patterns and sizes in the market.

There are mostly two patterns:

(a) Flat back for mounting on walls,

ADVERTISEMENTS:

(b) Angle back for fixing at the junction of two walls.

Flat back basins are provided with double or single tap holes. All the wash basins should be of one piece construction and should have slotted overflow hole. All the internal angles are designed so as to facilitate cleaning. The wash basins are provided with a circular waste hole in the bottom as shows in Fig. 25.1. The basins are provided with an integral soap holder recess which drains into the bowl.

Wash basins are made of fire-clay, stoneware, earthenware or vitreous china. But nowadays steel, aluminium and plastic wash basins are also available in the market which are very popular. In plain the basins may have rectangular, square, circular, oblong, circular quadrant etc. shape depending on the choice. Again these may be supported on the brackets fixed on the wall or supported on the pedestals.

ADVERTISEMENTS:

For holding water in the bowl these are provided with tapering rubber plugs, which can be fitted in the outlet. This plug is fixed to a chain secured by a stay.

The usual size of wash basins are:

Type # 2. Sinks:

These are rectangular shallow receptacles suitable for kitchens or laboratory. Fig. 25.2 shows a kitchen sink which is mostly used. It is of one piece construction, provided with or without rim.

The floor of the sink is given a slope towards the waste outlet. The sinks are provided with circular waste hole. All the kitchen sinks are provided with a draining board which is fixed on the right of the user. Weir type overflow slots are also provided in some sinks.

The usual dimensions of the sinks are:

The sinks are made of glazed earthenware or stoneware. The height of the top of the sink from the floor should be 90 cm.

Type # 3. Bath Tub:

ADVERTISEMENTS:

Bath tubs may be made of various materials, such as enamelled iron, plastic, cast iron, porcelain enamelled, marble or fire clay etc. For high class residential buildings marble, plastic or enamelled iron or fibre glass baths are used. For public places glazed fire-clay or porcelain enamelled cast iron baths are used.

Vitreous enamelled pressed steel baths are also available in the market. Previously copper baths were used but nowadays they have become obsolete. In future aluminium alloy and fibre glass bath are coming which will replace old baths.

Fig. 25.3 shows the section through a bath. The bath may be parallel or taper, the latter type being more popular. It is provided with one outlet of 4 to 8 cm and one inlet pipe for filling it. In some cases two taps are provided one for hot and another for cold water supply. The bath should also be provided with one over-flow pipe to take excessive water. The waste pipe of bath is provided with a trap, to prevent the foul gases from entering in the bath room.

The usual dimensions of bath are: length 1.7 to 1.85 m width 70 to 75 cm, depth near waste pipe side 43 to 45 cm, overall height with feet 58 to 60 cm.

Type # 4. Flushing Cisterns:

ADVERTISEMENTS:

These are used for flushing water closets and urinals after use. There are several varieties of flushing cisterns. High-level cisterns are intended to operate with a minimum height of 125 cm between the top of the pan and the underside of the cistern.

Low-level cisterns are intended to operate at a height not more than 30 cm between the top of the pan and the underside of the cistern. Cistern may be of cast iron, glazed earthenware, glazed vitreous ware or pressed steel or any other impervious material. Now a days plastic cisterns are also available in the market.

Following two types of cisterns are most common now a days:

(i) Bell type without valve.

(ii) Flat bottom type fitted with valve.

Fig. 25.4 shows the bells type flushing cistern. The bell is kept over the outlet pipe, the inlet end of which is slightly above the water level. When the chain is pulled the bell is lifted causing the water to spill over the outlet pipe and starting the siphonic action due to which the whole water rushes towards the outlet and flushes the W.C.

Due to shortage in the water supply, there was urgent demand to reduce the quantity of water consumption. All the flushing cisterns available and existing in the building fitting, discharge their full quantity of water even for small purposes or even when small quantity of water will sufficient for that purpose.

C.B.R.I. Roorkee has developed dual flushing cistern, which allows fractional or full discharge of cistern at a time. All the existing cisterns can be converted into dual flushing cisterns by making arrangements to cut the vacuum seal at the fixed water level. To obtain the fractional discharge the chain is pulled and left, but for obtaining full discharge the chain is pulled and kept in position till full capacity is discharged.

For converting the existing cisterns to dual flushing cisterns, 6 mm dia., rubber tube is fixed in the bell of the cistern at the fixed height. The other end of the rubber tube is connected to a plastic pipe with a stop-cock at the end to control the entry of air. The cistern will give full discharge with the stop cock and fractional discharge with the stop cock open.

C.B.R.I. has also developed an automatic flushing cistern for the urinals. This cistern has eliminated the use of copper fittings which are presently provided with the public urinals cisterns. The new developed fittings consist of a U-tube made of plastic pipe.

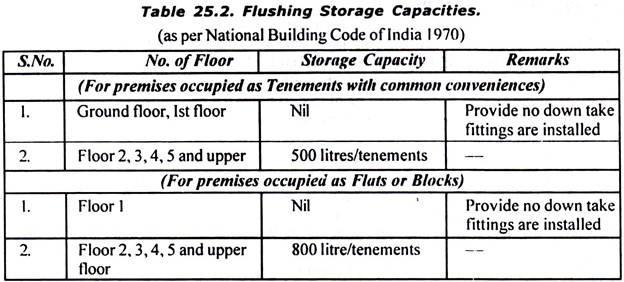

When the water level in the cistern reaches the level of the bend, the syphonic action takes place and the water present in the cistern rushes, to the urinals. This new automatic flushing cistern can be cheaply manufactured and easily fixed in the position. Table 25.1 gives the Flushing Storage Capacities.

Note:

1. If the premises is situated at a place higher than the road level in front of the premises, storage at ground level should be provided on the same lines on floor 2.

2. The above storage may be permitted to be installed provided that the total domestic storage calculated on the above basis is not less than the storage calculated on the number of down take fittings according to the scales given below:

(a) Down take taps – 70 Hires each

(b) Showers – 135 litres each

(c) Bath tubs – 200 litres each

Fig. 25.5. illustrates the flat bottom type flushing cistern provided with valve. When the chain is pulled, it lifts the disc which also suddenly lifts the water above it and starts the siphonic action. The valve allows the water to rush in the outlet pipe.

The flushing cisterns are provided with inlet pipe, over-flow pipe and automatic closing float ball valve.

Type # 5. Water-Closet:

This is a sanitary appliance to receive the human excreta directly and is connected to the soil pipe by means of a trap.

The water closets are classified as follows:

(A) Squatting type or Indian type:

(i) Long pan pattern (length 450,580,680 mm)

(ii) Orissa pattern (length 580,630,680 mm)

(iii) Rural pattern (length 425 mm)

(B) Wash-down, Pedestral or European type:

Fig. 25.6 shows the section through an Indian type water closet.

This is manufactured in two different pieces:

(a) Squatting pan, and

(b) Trap.

The pan is provided with an integral flushing rim of suitable type. The inside of the bottom of the pan should have sufficient slope towards the outlet for quick disposal during flushing.

These are made of vitreous chain clay. The inner portion is glazed to make it easy in cleaning. The pan is connected to the flushing cistern by means of flushing pipe. The top of the trap is connected to the anti-siphon or vent pipe.

Fig. 25.7 shows the pictorial view of an Indian type water closet.

Fig. 25.8 shows the section through a wash-down type water closet which is most commonly used in high class buildings. It is provided with a wide flushing rim and 5 cm trap. It is one piece construction in which the pan and trap are not separate. It is provided with an inlet or supply horn for connecting to the flushing pipe.

It may be provided with P and S trap as desired. These types of water closets require less space than squatting pattern type and can be flushed by low level cistern. Nowadays siphonic water closets are very popular. Fig. 25.9 shows the isometric view of such a water closet.

Type # 6. Urinals:

Urinals can be made in any of the following patterns and sizes:

Bowl type urinals are of one piece construction. Each urinal is provided with two fixing holes on the side for fixing it on the wall. At the bottom an outlet horn is provided for connecting it to the trap. The inside surface is regular and smooth for ensuring efficient flushing.

The bottom of the urinal is provided with sufficient slope from the front towards the outlet for efficient drainage of the urinal. Bowl type urinals are also provided with flushing rim which is connected by flushing pipe to the flushing cistern. Fig. 25.10 illustrates a bowl type urinal.

Fig. 25.11 shows the isometric view of two type urinals placed in position.

The slab and stall type urinals are manufactured either as a urinal or as a range of two or more and are used in public places such as cinema houses, restaurants, railway stations, offices, etc. The squatting plate urinals are mostly used in ladies lavatories and are on piece construction.