Materials Used for the Construction of Roads: Methods, Process, Layers and Road Pavement!

A wide variety of materials are used in the construction of roads these are soils (naturally occurring or processed), aggregates (fine aggregates or coarse aggregates obtained from rocks), binders like lime, bituminous materials, and cement, and miscellaneous materials used as admixtures for improved performance of roads under heavy loads and traffic.

Soil constitutes the primary material for the foundation, subgrade, or even the pavement (for low-cost roads with low traffic in rural areas). When the highway is constructed on an embankment at the desired level, soil constitutes the primary embankment material; further, since all structures have to ultimately rest on and transmit loads to ‘mother earth’, soil and rock also serve as foundation materials.

Soil is invariably used after some process of stabilisation such as compaction and strengthening by adding suitable admixtures for improving the performance of the road. Mineral aggregates obtained from rocks form the major component of the sub-bases and bases of highway pavements of almost all types.

ADVERTISEMENTS:

A detailed study of their properties is therefore essential. Binder materials such as bitumen and cement mixed with appropriate types and proportions of aggregates are used for the construction of superior types of roads that are characterised by their durability and load-carrying capacity. Thus, base courses, sub-base courses and even the surface or wearing courses require the use of these materials.

1. Soil:

Soils can be studied effectively if they are classified according to certain principles into a definite system. A system is an ordered grouping of certain elements in a discipline according to pre-defined principles. Just as classification or grouping is practised in scientific disciplines such as chemistry, zoology and botany, it is used in Geotechnical Engineering as well.

A soil classification system may be defined as a fundamental division of the various types of soil into groups according to certain parameters such as its physical properties, constituents or texture, field performance under load, presence of water and so on. There are a few field identification tests have been developed for preliminary identification in the field.

Need for Soil Classification:

ADVERTISEMENTS:

Soil deposits in nature are never homogenous in character; wide variations are observed in their properties and behaviour. Soils that exhibit similar average properties may be grouped as a class. Classification of soil is necessary to obtain an appropriate and fairly accurate idea of the properties and behaviour of a soil type.

A classification system is usually evolved with a view to assessing the suitability of a soil for specific use as a construction material or as a foundation material. In view of the wide variations in engineering properties of several soils, it is inevitable that in any system of classification, there will be borderline cases which may fall into groups that appear to be radically different under different systems of classification.

Hence, classification is taken only as a preliminary requirement to study the engineering behaviour of a soil; special tests may become necessary in any project of importance.

Requirements of a Soil Classification System:

ADVERTISEMENTS:

The general requirements of an ideal soil classification system are:

(i) It should have a scientific basis.

(ii) It should be relatively simple and objective in approach.

(iii) The number of groupings and properties used as the criteria should be limited.

ADVERTISEMENTS:

(iv) The properties considered should be relevant to the purpose of classification.

(v) A generally accepted uniform soil terminology should be used.

(vi) It should indicate the probable performance of the soil to a satisfactory degree of accuracy.

(vii) Group boundaries should be drawn as closely as possible where significant changes in soil properties occur.

ADVERTISEMENTS:

(viii) It should be acceptable to all engineers.

These are rather ambitious requirements and cannot be expected to be met by any system, primarily because of the complex nature of soil, which does not lend itself to a simple classification. Therefore, a soil classification system is probably satisfactory only for the specific engineering application for which it was developed.

Although several classification systems have been developed, some being relatively more elaborate and exhaustive than others, the following systems only will be considered:

(a) Textural classification

(b) PRA system of classification (Group index method)

(c) Unified soil classification System

(d) Indian Standard Soil classification system

(a) Textural Classification:

Textural or grain size classification of soil is based on the particle size of the soil. Terms such as gravel, sand, silt and clay are used to indicate the ranges of grain size. Natural soil is invariably a mixture of particles of various sizes.

Although several textural classifications have been proposed, including the PRA system, the MIT classification and the IS textural classification are considered here in view of their wider acceptance.

MIT Textural Classification:

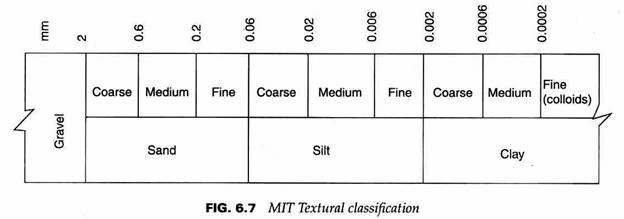

This was developed by the Massachusetts Institute of Technology, USA. The ranges of grain sizes in this scale, along with the soil designations, are given below (Fig. 6.7).

IS Textural Classification:

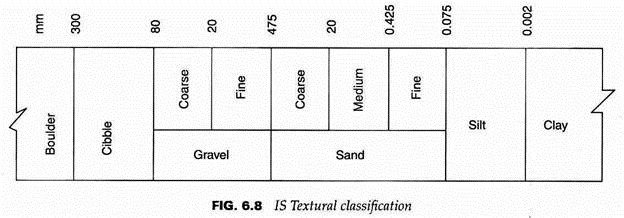

The ranges of sizes in the IS textural classification scale, along with the soil designations, are given below (Fig. 6.8).

This forms part of the Indian Standard Soil Classification System. In general, textural classifications are inadequate primarily because plasticity characteristics do not find any place in them.

(b) PRA System of Classification (Group Index Method):

The US Bureau of Public Roads developed a classification system, called the Public Roads Administration (PRA) classification system in 1931, specifically meant for use in road construction. This was revised several times, and the one given here is that revised in 1945 by the American Association of State Highway and Transport Officials (AASHTO). This system is based on both particle size and plasticity characteristics.

According to this system, soils are classified into eight groups—A-1 to A-8, the last one being Peat. Some groups contain a few subgroups. Soils within each group are evaluated according to the group index (GI), calculated from the following empirical formula –

GI = 0.2 a + 0.005 ac + 0.01 bd … (6.55)

Here,

a = that part of the percent passing US Sieve No.200 (IS-75 μm) greater than 35, and not exceeding 75, expressed as a positive whole number (1 to 40);

b = that part of the percent passing US Sieve No.200 (IS-75 μm) greater than 15, and not exceeding 55, expressed as a positive whole number (1 to 40);

c = that part of the liquid limit greater than 40, and not greater than 60, expressed as a positive whole number (1 to 20); and,

d = that part of the plasticity index greater than 10, and not exceeding 30, expressed as a positive whole number (1 to 25).

The group index value should be rounded off to the nearest integer; in case any of the above values is less than the minimum limit, it should be taken as zero.

In general, the greater the group index value, the less desirable the soil is for highway construction within that subgroup.

The details of the groups and subgroups are set out in Table 6.1.

Unified Soil Classification System:

This system was originally developed by Arthur Casagrande and adopted by the US Corps of Engineers in 1942 as ‘Airfield Classification’. It was later revised for universal use and re-designated as the Unified Soil Classification in 1953.

In this system, soils are classified into three broad categories:

(i) Coarse-grained soils with up to 50% passing No.200 American Standard Testing Service (ASTM) Sieve (75 μm-IS sieve).

(ii) Fine-grained soils with more than 50% passing No.200 ASTM Sieve (75 μm-IS sieve).

(iii) Organic soils.

The first two categories can be distinguished by their plasticity characteristics. The third can be easily identified by its colour, odour and fibrous nature.

Each soil component is assigned a symbol as follows:

Gravel – G

Silt: M (from the Swedish word, ‘mo’ for silt)

Organic – O

Sand – S

Clay – C

Peat – Pt

Coarse-grained soils are further sub-divided into well-graded (W), and poorly-graded (P) varieties, depending upon the uniformity coefficient (U) and the coefficient of curvature (Cc) –

Well-graded gravel, U > 4

Well-graded sand, U > 6

Well-graded soil, Cc = 1 to 3.

Fine-grained soils are subdivided into those with low plasticity (L), with ωL < 50%, and those with high plasticity (H), with ω L > 50%. The plasticity chart devised by Casagrande is used for the identification of fine-grained soils (Fig 6.9) –

Indian Standard Soil Classification System:

The relevant Indian Standard is “IS: 1498-1970, classification and identification of soils for engineering purposes (First Revision.)”.

The significant provisions of this system are given below:

Soil shall be broadly divided into three divisions:

(1) Coarse-grained soil – More than 50% of the total material by weight is larger than 75 μm IS sieve size.

(2) Fine-grained soil: More than 50% of the total material by weight is smaller than 75 μm IS sieve size.

(3) Highly Organic Soil and Other Miscellaneous Soil Materials:

These soils contain large percentages of fibrous organic matter such as peat and particles of decomposed vegetation.

In addition, certain soils containing shells, cinders and other non-soil materials in sufficient quantities are also grouped in this division.

Coarse-grained soils shall be divided into (a) gravels and (b) sands.

(a) Gravels – More than 50% of coarse fraction (+75 μm) is larger than 4.75 mm IS sieve size.

(b) Sands – More than 50% of coarse fraction (+75 μm) is smaller than 4.75 mm IS sieve size. Fine-grained soils can be subdivided into

(i) Silts and clays of low compressibility – Liquid limit less than 35% (L).

(ii) Silts and clays of medium compressibility – Liquid limit greater than 35% and less than 50% (I).

(iii) Silts and clays of high compressibility – Liquid limit greater than 50% (H).

Coarse-grained soils shall be further subdivided into eight basic soil groups, and the finegrained soils into nine basic soil groups; highly organic soils and other miscellaneous soil materials shall be placed in one group.

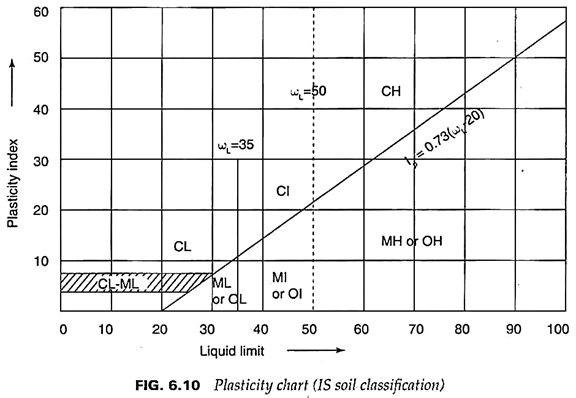

The Plasticity Chart used in IS system of soil classification is shown in Fig. 6.10.

Classification Criteria for Fine-Grained Soil:

Based on laboratory tests and the results in the form of consistency limits, the plasticity chart forms the basis for the classification of fine-grained soils.

Organic silts and clays are distinguished from inorganic soils which have the same position on the plasticity chart, by odour and colour. In case of doubt, the material may be oven-dried, remixed with water, and retested for liquid limit. The plasticity of fine-grained organic soils is considerably reduced on oven-drying.

Oven-drying affects the liquid limit of inorganic soils also, but only to a small extent. A decrease in liquid limit on oven-drying to a value-less than three-fourths of that before oven-drying is a positive identification of organic soils.

Black-Cotton Soils:

These are inorganic clays of medium to high compressibility. They are characterised by high shrinkage and swelling characteristics. When plotted on the plasticity chart, they lie mostly along a band above the A-line. For some, the band may lie below the A-lie also.

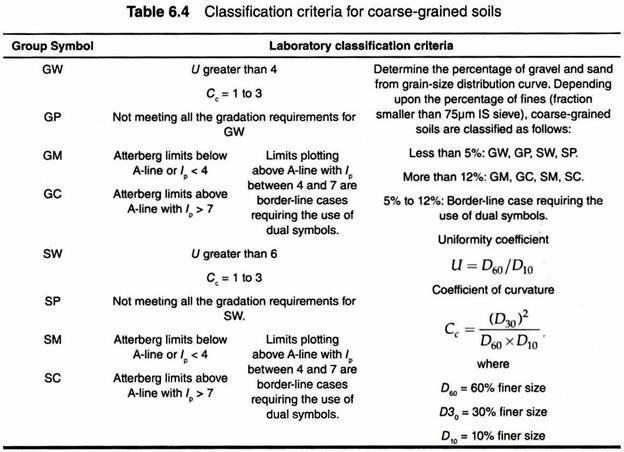

Kaolin behaves like inorganic silt and usually lies below the A-line; this shall be classified as such (ML, MI and MH), although it is clay from mineralogical stand point. The classification criteria for coarse-grained soils are given in Table 6.4.

Boundary Classification for Coarse-Grained Soils:

Coarse-grained soils with 5% to 12% fines are considered border-line cases between clean and dirty gravels or sands-for example, GW-GC, or SP-SM. Similarly, border-line cases might occur in dirty gravels and dirty sands, where Ip is between 4 and 7- for example, GM-GC, or SM-SC. It is, therefore, possible to have a border-line case of a border-line case. The rule for correct classification in such cases is to favour the non-plastic classification.

For example, gravel with 10% fines, a U-value of 20, a Cc -value of 2.0, and IP of 6 would be classified GW-GM, rather than GW-GC.

Note – Even separate flow-charts may be shown for coarse-grained and fine-grained soils.

Relatively Suitability for General Engineering Purposes:

The characteristics of the various soil groups pertinent to roads and airfields-value as subgrade, sub-base and base material, compressibility, drainage characteristics, compaction characteristics, dry unit weight, CBR-value, and subgrade modulus are all tabulated in “IS: 1498-1970 – classification and identification of soils for general engineering purposes”.

It also includes characteristics pertinent to embankments and foundations-values as embankment material, compaction characteristics, value as foundations material, requirements for seepage control, ranges of permeability and dry unit weight. Characteristics pertinent to suitability for canal sections compressibility, workability as a construction material and shearing strength when compacted and saturated are also given in relative terms or qualitative terms.

The information provided in IS: 1498-1970 serves the purpose of a guideline or an indication of the suitability of a soil based on the IS classification system. However, important and large projects need detailed investigation of the soil properties and engineering behaviour for good design.

2. Stone Aggregates:

Stone aggregate, or mineral aggregate, as it is called, is the most important component of the materials used in the construction of roads. These aggregates are derived from rocks, which are formed by the cementation of minerals by the forces of nature.

Stone aggregates are invariably derived by breaking the naturally occurring rocks to the required sizes. They are used for granular bases, sub-bases, as part of bituminous mixes and cement concrete; they are also the primary component of a relatively cheaper road, called water-bound macadam.

A study of the types of aggregates, their properties, and the tests to determine their suitability for a specific purpose is of utmost importance to a highway engineer. Properties such as strength and durability of aggregates are generally influenced by their origin of occurrence, mineral constituents and the nature of the bond between the constituents.

Geological Classification of Rocks:

Geologically speaking, rocks are classified into the following categories:

These are formed by the cooling, solidification and crystallisation of molten rock on the earth’s crust at different depths. The minerals, their proportions and the rate of cooling of the magma have a bearing on the strength characteristics of the rock.

Igneous rocks are, in general, stronger than the other two types. Granite, diorite and gabbro are intrusive rocks which form at deep layers in the earth’s crust. Basalt (or trap), andesite, rhyolite and dolerite are extrusive rocks which from at the top layers of the earth’s crust.

Fine material or rock fragments and particles transported by water or wind and deposited in layers, get hardened in course of time to form sedimentary rocks (the time required is on geologic scale). They consist of a layered structure; the rock beds are stratified, they may be porous, and have relatively low strength.

Examples of siliceous variety are sandstone and argellite; those of calcareous variety are limestone and dolomite.

These are formed by the modification and re-crystallisation of igneous rocks and sedimentary rocks by geological and natural agents such as temperature, pressure, moisture, humidity, and movement of rock beds.

Major changes occur in geologic time and form foliations. This kind of foliated structure makes these rocks comparably weaker than igneous rocks. Popular examples of metamorphic rocks are gneiss (from granite), slate (from shale) and schist.

Examples of un-foliated types are marble (from limestone) and quartzite (from sandstone). (Marble and gneiss are used for flooring and face work in buildings.)

Desirable Properties of Sand Aggregates:

The following properties are desirable in soil aggregates used the construction of roads:

(i) Strength:

It is the resistance to crushing which the aggregates used in road construction, especially in the top layers and wearing course, have to withstand the stresses due to wheel loads of the traffic in addition to wear and tear.

(ii) Hardness:

It is the resistance to abrasion of the aggregate at the surface. The constant rubbing or abrading action between the tyres of moving vehicles and the exposed aggregate at the road surface should be resisted adequately.

(iii) Toughness:

This is the resistance to impact due to moving traffic. Heavily loaded trucks and other vehicles cause heavy impact loads on the road surface while moving at high speeds, and while accelerating and decelerating. Even steel-typed vehicles, though moving slow, cause heavy impact on the aggregates exposed at the surface. Hence, resistance to such impact forces is a desirable quality.

(iv) Durability:

It is the resistance to the process of disintegration due to the weathering action of the forces of nature. The property by virtue of which the aggregate withstands weathering is called soundness. This is also a desirable property.

(v) Cementation:

It is the ability of the aggregate to form its own binding material under traffic, providing resistance to lateral displacement. Limestone and laterite are examples of stones with good cementing quality. This becomes important in the case of water-bound macadam roads.

(vi) Appropriate Shape:

Aggregates maybe either rounded, cubical, angular, flaky, or elongated. Each shape is appropriate for a certain use. Too flaky and too elongated aggregates have less strength and durability; so they are not preferred in road construction.

Rounded aggregates are good for cement concrete because of the workability such aggregates provide. Cubical or angular aggregates have good interlocking properties; since flexible pavements derive their stability due to interlocking, such aggregates are the preferred type for construction. Thus, the appropriate shape for a particular use is also a desirable property.

(vii) Adhesion with Bitumen:

The aggregates used in bituminous pavements should have less affinity to water than to bitumen; otherwise, the bituminous coating on the surface of the aggregate will get stripped off in the presence of water. So, hydrophobic characteristic is a desirable property for aggregates to be used in the construction of bituminous roads.

(viii) Attrition:

This is mutual rubbing of aggregates under traffic; adequate resistance to attrition is a desirable property.

(ix) Texture:

This is a measure of the degree of fineness or smoothness of the surface of the aggregate.

Gravels from river beds are fairly smooth; as a rule, fine grained rock is highly resistant to wear and is preferred for surface courses.

3. Bituminous Materials:

Bitumen was used as a bonding and water-proofing agent thousands of years ago. However, the use of bitumen for road-making picked up only in the nineteenth century. As the quest for fuels like petroleum to run automobiles grew and the distillation of crude oil emerged as a major refining industry, the residues known as bitumen and tar found increasing use in constructing bituminous surfaces, which provided superior riding surface.

The definition for the term, bitumen, given by the American Society for Testing Materials (ASTM) runs thus:

“Bitumen is a hydrocarbon material of natural or pyrogenous origin, which is in a gaseous, liquid, semi-solid, or solid state, and which is completely soluble in carbon disulphide (CS2).”

Of course, bitumen is found to be soluble to a large extent in carbon tetrachloride (CCl4) also. Bitumen is a complex organic compound and occurs either as such in nature or can be obtained during the distillation of petroleum; it is generally non-volatile and resistant to most acids, alkalis and salts.

Bitumen occurring in nature as rock intrusions invariably contains inert inorganic materials or minerals; in such a case it is called asphalt. It is also found in lakes (as in Trinidad), in which case it is called lake asphalt. However, in American terminology, bitumen itself is termed asphalt, irrespective of whether it contains inorganic/mineral matter or not. In India, the British terminology is used for the terms bitumen and asphalt.

Important Properties of Bitumen:

1. Predominantly hydrocarbons, with small quantities of sulphur, nitrogen and metals.

2. Mostly (up to 99.9%) soluble in carbon disulphide (CS2), and insoluble in water.

3. Softens on heating and gets hardened on cooling.

4. Highly impermeable to water.

5. Chemically inert and unaffected by most acids, alkalis and salts.

6. No specific boiling point, melting point or freezing point; a form of ‘softening point’ is used in their characterisation.

7. Although generally hydrophobic (water repellent), they may be made hydrophilic (water liking) by the addition of a small quantity of surface-active agent.

8. Most bitumens are colloidal in nature.

Desirable Properties of Bitumen as a Road Material:

1. Workability – Bitumen should be fluid enough at the time of mixing so that the aggregates are fully coated by the binder. Fluidity is achieved either by heating or by cutting back with a thin flux or by emulsifying the bitumen.

2. Durability – There should be little change in viscosity within the usual range of temperatures in the locality.

3. Volatile constituents in bitumen should not be lost excessively at higher temperatures to ensure durability.

4. It should have enough ductility to avoid brittleness and cracking.

5. Strength and adhesion – The bitumen should have good affinity to the aggregates and should not be stripped off in the continued presence of water.

6. Cost-effectiveness.

A few more terms relating to bitumen/asphalt are:

Straight-Run Bitumen:

Bitumen derived from the refining of petroleum for which the viscosity has not been adjusted by blending with flux oil or by softening with any cut-back oil or by any other treatment. It generally has high viscosity.

Asphalt Cement:

A binder consisting of bitumen, or a mixture of lake asphalt and bitumen or flux oils, specially prepared as per prescribed quality and consistency for direct use in paving, usually in the hot condition.

Oxidised or Blown Bitumen:

Bitumen obtained by further treatment of straight-run bitumen by running it, while hot, into a vertical column and blowing air through it. In this process, it attains a rubbery consistency with a higher softening point than before.

Cut-Back Bitumen:

Asphalt/bitumen dissolved in naphtha or kerosene to lower the viscosity and increase the workability.

Emulsified Bitumen:

A mixture in which asphalt cement, in a finely dispersed state, is suspended in chemically treated water.

Liquid Bitumen:

Include cut-backs in naphtha and kerosene, as also emulsified asphalts.

Flux-Oil:

A bituminous material, generally liquid, used for softening other bituminous materials.

Bitumen from Petroleum Refining:

The main source of bitumen is petroleum crude. Refining of petroleum crude involves fractional distillation. The crude oil is heated in a tube-still to about 200°C to 400°C and injected into a fractionating column. As the pressure is suddenly reduced, the volatile fractions with low boiling points get vaporised and go up the column, from where they are carried through condensers.

Gasoline, kerosene, diesel oil, and lubricating oils, constituting the light, medium and heavy distillates with gradually increasing boiling points, thus get collected. The heavy residue left at the bottom is collected as bitumen. Steam is injected into the fractionating column to help in the separation process of the fractions. The steam and vacuum distillation process is only a physical process and does not involve any chemical changes.

In modern refining processes, the distillation is carried out in stages. In the first stage, the temperature in the tube-still is kept relatively low (say 300°C to 350°C) and the light and medium fractions are separated in the fractionating column operating at atmospheric pressure.

The crude left is then passed through another still for subsequent transfer to another column operating under vacuum and injected with steam. The latest process dispenses with steam and relies on dry vacuum only, thus enabling a wide range of bitumen to be produced.

Paraffinic crudes yield, on distillation, an undesirable wax-like residue. Naphthenic crudes yield practically wax-free bitumen; crude from middle-east yields good bitumen. The heavy residue may be blown with air at high temperature in a converter to produce air-blown or oxidised bitumen.

They are stiff even at high atmospheric temperatures. Such bitumen are not used for pavements, but are good as roofing materials and water-proof paints. It is also used as filler material for cracks and joints in concrete pavements.

A schematic flow-chart for petroleum refining is shown in Fig. 6.65.

Cut-back bitumen is one, the viscosity of which is reduced by adding a volatile diluent. Penetration grade bitumens require to be heated to a specified temperature to lower its viscosity before it is applied on a road to facilitate coating the pre-heated aggregate. To obviate the need for heating the aggregate, cut-backs come in handy. Upon application, the volatiles slowly evaporate, and leave behind the original bituminous binder.

There are three types of cut-backs based on the diluent (dilutant or solvent) used:

1. Rapid-curing (RC) cutback – Bitumen blended with gasoline or naphtha, (highly volatile, low viscosity)

2. Medium-curing (MC) cutback – Bitumen blended with kerosene or coal tar creosote oil (medium viscosity)

3. Slow-curing (SC) cutback – Bitumen blended with gas oil (low viscosity, highly viscous)

Each of these has been categorized based on their initial kinematic viscosity values as follows:

1. RC 70, RC 250, RC 800, RC 3000

2. MC 30, MC 70, MC 250, MC 800, MC 3000

3. SC 70, SC 250, SC 800, SC 3000

Further details and specifications for these cutbacks are given in “IS: 217-1988: Specification for cutback bitumen, Bureau of Indian Standards, New Delhi, 1993”.

Since cutbacks contain volatile solvent, some of which may enter water bodies and air, they may cause environmental pollution. Also, since the solvent is inflammable, it may increase the possibility of fire hazard and cause concerns related to safety during handling and application. Therefore, cutbacks are being gradually replaced by emulsions.

A bitumen emulsion is obtained by blending bitumen with water and an additive called an emulsifier. The emulsified suspension contains dispersed minute particles of bitumen (that is, oil in water). In a bituminous emulsion, bitumen is the ‘dispersed’ phase (minutely subdivided particles), while water is the ‘continuous’ phase in which it is not soluble. The amount of bitumen to be mixed with water may range from 40 to 70% depending upon the intended use of the suspension.

Based on the type of emulsifier used, the bitumen particles can be negatively charged or positively charged. If they are negatively charged, ‘anionic bitumen emulsions’ are obtained, and if they are positively charged, ‘cationic emulsions’ are got.

Fatty acids derived from mineral, vegetable or wood sources saponified with sodium or potassium hydroxide are used as emulsifiers for producing anionic emulsion. For cationic emulsions, the emulsifiers are generally amine salts produced by the reaction of organic amine or diamine with acetic acid or hydrochloric acid.

The type of emulsion should be selected based on the mineral composition of the aggregate used for the bituminous mix. For example, for an aggregate rich in silica (SiO2) which has a strong electronegative charge on the surface, cationic emulsions are suitable with electropositive charge on the suspended bitumen particles. The mix then becomes electrostatically stable and produces a strong layer when compacted.

Bitumen emulsions, like cutback bitumens, are also classified into three types based on their setting times:

1. Rapid-setting emulsions (RS)

2. Medium-setting emulsions (MS)

3. Slow-setting emulsions (SS)

Setting, in this context, means separation of the emulsion. When the water in the emulsion evaporates, the minute bitumen particles in the emulsion coat the surface of the aggregates; curing takes place, by which the compacted layer of the emulsion-aggregate mix hardens and attains strength. Therefore, rapid-setting emulsion sets and cures in a relatively quick manner.

“IS: 3117-2004: Anionic bitumen emulsions” covers anionic emulsions, while “IS: 8887- 2004: Cationic bitumen emulsions” covers cationic emulsions.

Setting and curing of emulsion mixes are affected by the following factors:

(i) Gradation, dust, dampness, water absorption and mineral composition and surface charge of/on the aggregates.

(ii) Ingredients and quantity of the emulsion used.

(iii) Meteorological conditions like climate, weather, temperature, humidity, wind velocity, etc.

(iv) Drainage conditions of the construction site.

Advantages of Emulsions:

1. Emulsions can be used under cold and damp weather conditions.

2. Strength properties of bitumen are preserved as they do not need hot mixing.

3. Better coating of aggregates due to low viscosity of the emulsion.

4. Ideal for patch repair work and sealing of cracks as no heating is required and better penetration into even minute cracks is possible.

5. Water-based nature of the emulsions makes them environment-friendly.

6. A lot of energy is conserved as there is no need for intensive heating (only warming is needed, if at all.)

Limitations of Emulsions:

1. The nature of the aggregate has to be verified before choosing an appropriate emulsion.

2. Setting time varies not only with the type of emulsion, but also with atmospheric conditions at the time of application.

3. Based on the particular need, care should be exercised in choosing the type of emulsion and the quantity needed for the desired grade of bituminous mix.

4. Storage time is relatively restricted.

5. Bitumen emulsions are more expensive than hot-mix bitumen.

6. In general, emulsion-based bituminous pavements using emulsions are not as good as hot- mix constructions for heavy traffic loads.

Specifications for paving bitumen are to be appropriately chosen based on the particular need and the Indian Standard specifications listed below:

IS: 1203, 1205, 1206 (Parts 2 & 3), 1208, 1209 and 1216 (1978, 2002) for tests.

IS: 73-2006 for paving bitumen.

IS: 217-1988, 1993 for cutback bitumen.

IS: 3117-2004 for anionic bitumen emulsions.

IS: 8887-2004 for cationic bitumen emulsions.

Specifications for paving grade bitumens (IS: 73-2006):

Tar:

Tar is a black or brown to black, viscous, non-crystalline material having binding property. This is, therefore, the other category of bituminous materials.

Tar is obtained from the destructive distillation of organic materials such as coal, petroleum, oil, wood and peat, in the absence of air at about 1000°C. It is completely soluble in carbon tetrachloride (CCl4). It contains more volatile constituents than bitumen and is therefore more susceptible to change in temperature. Generally, tar is used for surface dressing on the wearing course since it has good adhesion in damp conditions.

Some more terms relating to tar are:

1. Coal tar – Tar produced by the destructive distillation of bituminous coal.

2. Coke-oven tar – A variety of coal tar obtained as a by-product from the destructive distillation of coal in the production of coke.

3. Oil-gas tar – A petroleum tar produced by cracking oils at high temperature in the production of oil-gas.

4. Water-gas tar – A petroleum tar produced by cracking oils at high temperature in the production of carburetted water-gas.

5. Refined tar – Produced from crude tar by distillation to remove water and to produce a residue of desired consistency.

6. Road tar – A tar refined in quality and consistency for use in paving of roads.

7. Pitch – Black or dark brown solid cementitious residue which gradually liquefies when heated and which is produced by distilling off the volatile constituents from tar.

Specifications for Road Tars:

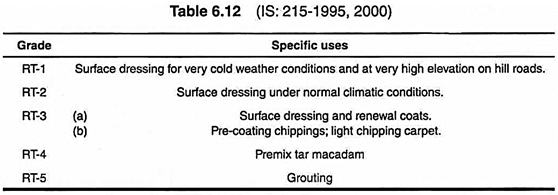

Indian Standards classify road tars for paving purposes into five grades — RT1, RT2, RT3, RT4, and RT5, meant for specific purposes.

These are covered by “IS: 215-1995: Road tar: Specifications, Bureau of Indian Standards, New Delhi, 2000”.

The grades and specific uses are given below in Table 6.12:

Standard specification for road tars of the five standard grades based on the properties determined from tests on tar are given in the Table 6.13 [IS: 215-1995, 2000].

Low Temperature Tar:

The coal-tar produced in the manufacture of coking coal requires carbonation at high temperatures above 1000°C. In view of the increasing demand for road tars in recent years, a new technology known as low temperature carbonisation has come into vogue.

In this, the carbonisation of coal is carried out in the temperature range of 600°-750°C in a smokeless fuel process. The crude tar thus produced is successfully used for making road tars; these are known as low temperature tars.

Bitumen versus Tar:

A comparison of bitumen and tar is given below:

(i) Aggregates coated with tar exhibit lower stripping action than those coated with bitumen.

(ii) Tar is more susceptible to temperature than bitumen. It becomes liquid at relatively lower temperature.

(iii) Tar is not easily dissolved in petroleum solvents; so it can be preferred for paving parking areas, where oils might drip from vehicles.

(iv) Since more setting time is required for tar, it may be processed at a mixing plant and carried to the construction site.

(v) In view of the higher free carbon content, tar is more brittle than bitumen.

(vi) As tars have more phenol content, they can get more easily oxidised than bitumen.

(vii) At higher temperatures, tar may be more easily affected than bitumen.

(viii) As more time is required for tar to set, tar-paved roads need to be closed to traffic for a longer time.

(ix) Both bitumen and tar appear black in colour in a large mass, but appear brown in thin films.

Tar-Bitumen Mixtures:

A mixture of tar and bitumen provides a binder of excellent quality as it has a decreased volume of insoluble benzene is decreased. Such mixtures have lower temperature susceptibility and reduced penetration value. Rheological properties of the binder also get altered. Generally, a mixture of tar and bitumen in equal proportions is considered to be an ideal binder.

Bituminous mixes for paving purposes consist of coarse aggregate, fine aggregate, filler material, bitumen, and air voids, suitably proportional and blended to provide a strong, stable and durable pavement.

The main aim of mix design is to determine the optimum bitumen content that will hold the mineral aggregates of suitable gradation together as a compact layer that resists the traffic loads. The mix should have a certain minimum air voids to allow volume changes during service either because of temperature changes or repeated loading from the traffic.

Requirements of Bituminous Mixes:

The following are the important requirements of bituminous mixes for pavements:

(i) Stability:

This is the resistance to deformation under traffic loads; it is a function of inter- particle friction and cohesion offered by the bitumen binder. It is related to the density of the mix which is dependent on the voids content. The more the density, the more stable the mix; however, a minimum voids content is necessary to allow for volume changes which cannot be fully prevented.

(ii) Durability:

This is the resistance to weathering action and abrasion from traffic. Spalling, stripping and formation of pits, corrugations and potholes can result from weathering and traffic. Excessive strain may cause cracking or plastic failure.

(iii) Flexibility:

This is a measure of the resistance to long-term deformations and shapes of the road base, sub-base and subgrade; this depends on the flexural or bending strength of the pavement.

(iv) Skid Resistance:

The resistance of the surface of the pavement laid with the bituminous mix to skidding of the tyres of vehicles is called skid resistance. The surface texture should be such as to provide grip or friction even under wet conditions. This is important in the prevention of accidents.

(v) Workability:

This is the ease with which the mix can be placed in position and compacted. It depends on the aggregate characteristics like the size, shape texture and gradation, bitumen content and nature of the bituminous material.

(vi) Economy:

The overall cost in achieving the desired qualities of the mix and the pavement should be a minimum, consistent with quality.

The desired qualities of the bituminous mixes, therefore, have to be achieved by:

1. Using good quality aggregate, which is hydrophobic and has rough surface texture, with appropriate grading and voids content.

2. Using bituminous binder of the correct quality and consistency based on the specific purpose for which the pairing mix is intended.

3. Controlling the voids content and the bitumen content to achieve the desirable qualities listed above.

4. Cement, Cement Mortar and Cement Concrete:

Cement concrete is a versatile material which has revolutionised civil engineering construction during the twentieth century. A fresh cement concrete mix consists of cement, mineral aggregates (coarse aggregate and fine aggregate), and water.

A well-designed cement concrete mix sets and hardens due to the binding property of the cements, forms a mix with minimum void space and on curing with water, provides a strong, stable and durable pavement for a highway, resisting repetitive impact from wheel loads and also withstanding adverse environmental conditions.

Thus, a cement concrete pavement is the most superior highway construction primarily from the point of view of strength and durability. The ingredients of the concrete mix, viz., the coarse aggregate (broken stone) and fine aggregate (sand) have to be selected carefully to satisfy the desirable properties for concrete-making. Potable water is generally considered satisfactory making cement concrete.

Cement is used also as an additive to soil to produce soil-cement used as the primarily material in the construction of low-cost roads.

Cement is the most important ingredient of cement concrete or cement mortar (cement mortar is a suitable mixture of cement and fine aggregate or sand in appropriate proportions).

Cement mixed with water becomes a paste and spreads over the aggregates forming a thin film; chemical reactions take place leading to the formation of silicates and aluminates. Subsequently, setting takes place and in the presence of water, hydration takes place leading to hardening of the concrete.

The most common cement is what is now known as the Ordinary Portland Cement (OPC). Calcareous and silicate compounds are blended and heated to high temperatures (1500°C) to form clinkers of new chemical compounds, which when ground to fine particles result in ‘cement’.

The primary ingredients of cement are:

(i) Tricalcium silicate (3CaO.SiO2) ≈ 50%

(ii) Dicalcium silicate (2CaO.SiO2) ≈ 22%

(iii) Tricalcium aluminate (3CaO.Al2O3) ≈ 9%

(iv) Tetracalcium aluminoferrite (4CaO.Al2O3.Fe2O3) ≈ 9%

(v) Miscellaneous compounds ≈ 10%

The silicates contribute to the immediate strength gain while the other ingredients are responsible for the long-term strength gain. The properties of cement can be modified by blending it in different admixtures in the manufacturing process.

The following are the different types cements widely used for specific purposes in India:

1. Ordinary Portland cement (OPC)

2. Rapid hardening cement

3. High alumina cement

4. Low heat cement

5. Portland blast furnace slag cement

Ordinary Portland cement is classified into three grades:

Grade 43 cement is widely used for highway pavements since its heat of hydration and shrinkage cracks are less compared to OPC 53 grade.

Rapid hardening cement is preferred for remedial jobs when rapid gain of strength is necessary to restore the pavement to traffic in a short duration.

The important properties of cement are:

1. Fineness:

This is related to grain size and specific surface. Fineness is a desirable feature because it is related to the intensity of hydration and strength gain. Sieve analysis is the simplest and the most direct method to determine the fineness (IS: 269-1993). Dry cement retained on IS-90 p sieve should not be more than 10% for OPC and 5% for rapid-hardening cement.

2. Setting Time:

Workable cement mortar paste using a desired water-cement ratio is prepared and the time taken for the paste to harden is noted; setting time is an indication of initial chemical reactions of cement.

Temperature and humidity affect setting time. The standard values for testing are 20±2°C and 65% respectively. Setting times are classified into initial and final setting time. Initial setting time is important for transporting, placing and compaction of concrete. The minimum initial setting time for OPC should be at least 30 min. (IS: 269-1993).

The final setting time is the time required for the concrete to harden sufficiently to attain the shape of the mould in which it is poured. By this time, primary chemical reactions are completed. This is important for the removal of form work. The maximum final setting time is about 10 hours for OPC (IS: 269-1993).

3. Soundness:

This is the ability to resist volume changes as a result of the channel reactions with water. The Le Chatelier test and the autoclave test are used to verify the soundness (IS: 269-1993).

4. Chemical Composition:

The lime saturation factor (LSF) of a cement is the ratio of Calcium Oxide (CaO) to the other three main oxides present in it.

5. Strength:

This is usually determined by testing cement mortar or cement concrete cubes or cylinders for compression, tension and flexural strength. Compressive strength is the most important property; for OPC, it should not be less than 16, 22 and 33 MPa at 3, 7 and 28 days of curing (IS: 269-1993).

Admixtures for Cement Concrete:

Different types of additives — chemical compounds, synthetic polymers and resins are blended with cement concrete while mixing, to modify its properties. Setting times, workability, strength and durability can be modified by reducing water and cement and adding admixtures. (IS: 9103 and IS: 6925)

Some admixtures used are:

1. Retardants – Increase the setting time of cement concrete.

2. Accelerators – Accelerate hydration for rapid strength gain.

3. Plasticisers and super-plasticisers – Increase the workability of concrete, reduce the water content needs and reduce the heat of hydration

4. Air-entraining agents – Improve workability and increase resistance to frost action.

5. Pigments – Impart colour to the cement concrete mix for aesthetic purposes.

Miscellaneous Admixtures:

Fly ash, blast furnace slag, pond ash, rice husk ash, calcined clay and other mineral additives supplement cementing properties, and act as partial substitutes for cement for achieving some degree of economy.

Properties of Cement Concrete:

Workability:

This is a property of fresh concrete. The ease of placement is workability. Slump test and compaction factor test are generally used to assess the workability of concrete (SP: 23-1982). Generally, ‘slump’ ranges from 25 to 125 mm. The prescribed compaction factor values are of the order 0.75 to 0.80 (IS: 456-2000 & IS: 1199-1959)

Tests on hardened concrete are for compressive strength, flexural strength, split (or indirect) tensile strength and elastic modulus [IS: 516-1999 & IS: 5816-1999].

The Poisson’s ratio for normal concrete in Indian conditions may be taken as 0.15. More details may be found in the relevant Indian Standard Specifications cited.

Design of Cement Concrete Mix:

The relevant standards are:

These are considered out of scope of the present treatment.